10-14-2005, 09:09 PM

|

|

Registered User

|

|

Join Date: Feb 2003

Location: Crystal River, Florida USA

Posts: 396

|

|

|

I'm not 100% sure, but I think that the magnets in the motors are identical (all ZipZaps cars motor magnets are the same, and all ZipZaps MT motor magnets are the same.).

(Just had a thought):

One thing (per my previous post about the wood chips/pine needles), my runtimes aren't all that good when plowing through the pine needles and forest underbrush. I now have a hunch that although the slowest (stock) MT motor doesn't have as much torque as the the fastest motor that I now currently use, the stock motor just might _appear_ to have more torque (when I finally get around to testing it out), simply for the fact that it has less drain on the battery than the fastest motor.

Example/in other words: The (stock) MT motor will run at a slightly higher voltage for a slightly longer period of time than the fastest MT motor (due to it drawing less current than the fastest motor), increasing the length of the runtime, and then in turn won't bog down as easy or as quickly.

Anyhow, I'm going to try the afore mentioned torque tests when I get a chance (been too tired to think after - still not finished yet - spreading around over 2 tons of wood chips out here in the woods <LOL>).

Last edited by rfnagel; 10-14-2005 at 09:13 PM.

|

10-16-2005, 01:10 AM

|

|

Registered User

|

|

Join Date: Nov 2004

Location: New Zealand

Posts: 174

|

|

I just say ask NAMUNA to run some tests

|

10-16-2005, 07:21 AM

|

|

Registered User

|

|

Join Date: Sep 2005

Location: Williamsport, PA

Posts: 12

|

|

Quote:

Originally posted by SamDrummerBoy

I was hoping that I was wrong. I want to find a high torque motor. More than what is available from rs. Has anyone found a way to change magnets or anything? Maybe you could pull the manets out of a fast motor and put them in a torque wound motor. (similar to the "spin brush" idea in xmods.) Does anyone have any way of testing magnetic strength? I don't. I would love to know if that could be done. I just hate to waste motors if it can't.(Don't get me wrong I will if noone can messure magnetic stength on the motors.)

|

You can electrical tape magnets to the outside of the motor 'cans' and that will add power to the motor. You just have to play with the placement of the magnets until you get what you want. I used to use rare earth magnets. You have to use them in pairs, and they attach using thier magnetic attraction. If they repel, they are in the wrong place or orientation. It's an old modle boat trick to gain torque and RPMs.

|

10-16-2005, 08:52 AM

|

|

I really should change my title...

|

|

Join Date: May 2003

Location: I have no frickin idea

Posts: 193

|

|

|

What size are those bearings? And how do you mount the body with an articulate monster?

|

10-16-2005, 09:04 AM

|

|

zipped up tight!

|

|

Join Date: Oct 2002

Location: MA

Posts: 428

|

|

Quote:

Originally posted by GerG

What size are those bearings? And how do you mount the body with an articulate monster?

|

I don't think it matters what size the bearings are...as long as they are small. It's easier to find a bearing, then find a drive shaft to fit, instead of the other way around. I used the bearings from one of those small PC chipset fans.

You'll have to improvise with the body mounting...putting tabs on the sides is one way.

|

11-06-2005, 06:59 PM

|

|

Bit Crazy

|

|

Join Date: Oct 2003

Location: Between the furnace and the water heater

Posts: 206

|

|

I just made a floating front clip out of a bit axle. Just bend it into an "L" and use hot glue to attatch it to the front of the chassis. It works very well......

|

11-07-2005, 02:43 PM

|

|

zipped up tight!

|

|

Join Date: Oct 2002

Location: MA

Posts: 428

|

|

|

so does the whole body articulate with the rear end? That could be an interesting concept!

|

11-07-2005, 07:34 PM

|

|

Bit Crazy

|

|

Join Date: Oct 2003

Location: Between the furnace and the water heater

Posts: 206

|

|

|

You got it....I added a thin peice of plastic to the rear tab to make the tolerance tighter. It's harder to get the shell on the rear clip, but once it's in, it's solid

|

05-23-2006, 12:15 AM

|

|

I process, therefore I am

|

|

Join Date: Nov 2002

Location: Savannah, GA USA

Posts: 1,075

|

|

|

I know this is an old thread, but I was wondering if Diets could tell me where that Unimog body posted in the link to the german site can be found by a tinkering Yank? It's larger than the TTTT bodies I've seen and I'm wondering about the scale and manufacturer. A link would be cool if it's possible.

And, I'm really liking the wheel weight idea. I think a mold of the wheel made in silicone, then plaster knock offs of the wheel cast in these molds would make plaster wheels that would take molten lead with no problem. Or, maybe finding and molding a suitable washer that will fit and then casting that in lead.

I used to melt (smelt?) lead on the stovetop years ago to make sand castings. It melts quite easily, but is very dangerous.

__________________

If it ain't broke, tear it apart and see what makes it tick!

Last edited by Azimov; 05-23-2006 at 12:22 AM.

|

05-24-2006, 01:40 AM

|

|

Registered User

|

|

Join Date: Jan 2005

Posts: 20

|

|

|

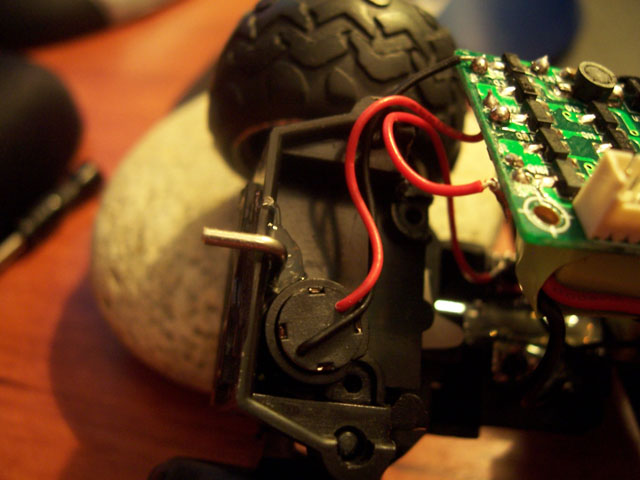

hehehe i didnt do the bearing or the shaft all i did was wedge a smal piece of plastic to hold the shaft in place.

it actualy works, but there is a lot of play. I will probably do the bearing mod to clean up the movement.

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -5. The time now is 08:18 AM.

|

|